See that rough looking edge there on the left? Blah...Looks messy, doesn't it? Not only that...it can be kind of...sharp. Yeah, it sounds odd but it's a little sharp so I bevel the edges to tidy it up and to help with the "twirl" action. What's that? What's twirl action, you ask? You know how you grab that bar of soap in your hand and spin it round and round and round to work up the lather? Yeah, that. That's twirl action.

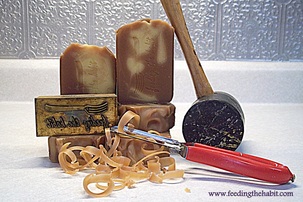

The first trick of the trade is dig out the trusty old vegetable peeler. You got it...a vegetable peeler. All that I want to do is to take off that sharp edge and the peeler works wonders.

When choosing a stamp it was important to me to find one that was American made. I found a nice little business in Washington state to make it for me. The stamp is made from from brass plate. Very sturdy and long lasting.

Depending on the how long it's been since the soap was made will determine how much "whack" I have to have to apply to get a decent imprint.

Watch out for those fingers. One wrong move and ouchie wowzers. Ask me how I know.

After 6 weeks then they can be wrapped with a label and a shrink wrap band. Then once again stored until they're sold.

Nothing too glamorous about this part of soapmaking and truthfully, it's not even necessary. I could leave the edges sharp and I really don't have to bother with stamping it. But I prefer to have a high quality product and it's the attention to details that help make it so. I do that for me. I do that for you. ☺ We deserve high quality stuff don't we?

Stay sudsy, my friends. Stay Sudsy!

RSS Feed

RSS Feed